We provide you with high-quality products with advanced design concepts and manufacturing technology

It consists of the following parts:

- A cylindrical evaporation chamber, usually heated by steam or thermal oil;

- A rotor driven by an electric motor via belt or direct connection;

- a fabricator welded to the rotor;

- a dynamic defoamer to remove any liquid droplets that may be trapped in the material vapour;

- A double-ended mechanical seal.

Advantages:

- In order to find the best solution for your product, we have different types of rotors available;

- Rotors are dynamically balanced to minimise vibration and final balancing is carried out on the assembled machine to achieve the best possible accuracy;

- Double-ended mechanical seals with liquid flushing system;

- Bottom shaft sleeve with auxiliary lubrication connection;

- Side discharge option available so that the bottom cone and tube do not need to be removed when replacing the bottom sleeve;

- The evaporation chamber is machined before polishing to ensure minimum clearance to the rotor, thus greatly improving the performance of the thin-film evaporator.

Areas of application for the thin film evaporator:

- Products that cannot be processed with conventional equipment due to very high viscosity or high solids content;

- Products requiring short residence times and low temperature treatment due to temperature sensitivity;

- Processes requiring high mass transfer in addition to heat transfer requirements, such as reaction, vapour extraction of volatiles and deodorisation.

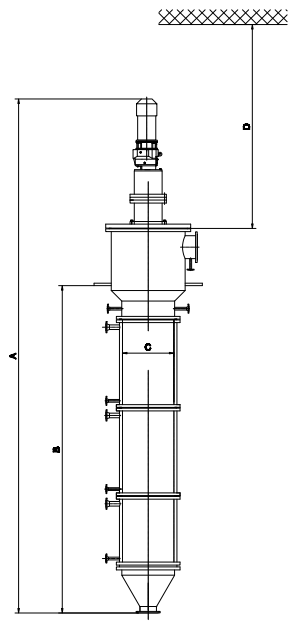

| TFE Vertical Thin Film Evaporator | |||||||

| Model | Heat Exchange Area | A | B | C | D | E | F |

| TFE 85/.15 | 0.15 | 1730 | 1100 | 85 | 1500 | 250 | 350 |

| TFE 100/.3 | 0.30 | 2050 | 1350 | 100 | 2000 | 280 | 400 |

| TFE 200/.75 | 0.75 | 3100 | 1715 | 200 | 3000 | 500 | 550 |

| TFE 250/1.3 | 1.30 | 3790 | 2270 | 250 | 4000 | 520 | 600 |

| TFE 320/2.3 | 2.30 | 5150 | 3160 | 320 | 5400 | 640 | 670 |

| TFE 400/3.5 | 3.50 | 5810 | 3600 | 400 | 6150 | 900 | 780 |

| TFE 450/4.5 | 4.50 | 6745 | 4200 | 450 | 7150 | 900 | 910 |

| TFE 600/6 | 6.00 | 7265 | 4400 | 600 | 7800 | 1400 | 1140 |

| TFE 700/7.5 | 7.50 | 7850 | 4750 | 700 | 7500 | 1400 | 1250 |

| TFE 700/9 | 9.00 | 8550 | 5450 | 700 | 8900 | 1400 | 1250 |

| TFE 850/10.5 | 10.5 | 8695 | 5550 | 850 | 9000 | 1600 | 1480 |

| TFE 850/12 | 12.00 | 9530 | 6100 | 850 | 10050 | 1600 | 1480 |

| TFE 1000/16 | 16.00 | 10200 | 6500 | 1000 | 11000 | 1700 | 1625 |

| TFE 1000/20 | 20.00 | 11600 | 7700 | 1000 | 12600 | 1700 | 1625 |

| TFE 1300/25 | 25.00 | 12150 | 7900 | 1300 | 12700 | 2000 | 1950 |

| TFE 1400/32 | 32.00 | 13650 | 9600 | 1400 | 14600 | 2200 | 2080 |

| TFE 1700/40 | 40.00 | 16750 | 11000 | 1700 | 16700 | 2500 | 2450 |

If you have any questions, feedback or comments, please fill out the form below and we will get back to you as soon as possible.

3B-301-2,No.143 ZhuZhou Road, Qingdao, China

+86-532-80626809

© 2023 Qingdao DoVere Precise Machinery Co., Ltd. All rights reserved 鲁ICP备09064072号-10 Powered by:Hicheng